Vacuum System

This Mark 50 system is upgraded by vertically mounting a VAT high vacuum valve to the chamber for direct cryopump access. Its vertical sealing plane prevents falling particles from interfering with the seal. The horizontal, 32-by-32 inch cylindrical chamber, offers a low profile for easy loading and unloading. The unique slide-down door minimizes floor-space requirements. The system is designed for fast servicing as well as operator efficiency. The pumping array can be quickly released from the chamber, and the trap array rolls out.

Sources

The CHA Mark 50 can be supplied with any type of source that is commercially available.

Heating

The system can be equipped with quartz-lamp heaters of up to 16 kW to produce wafer temperatures of over 500°C. The chamber design accommodates either conventional or backside heater placement.

Ion Beam Option

An optional ion beam source can be integrated into the Mark 50 to achieve a pre-cleaning action prior to deposition for removal of water vapor and other matter from the substrate surface. During the deposition cycle, the ion beam operates to etch the surface, enhancing deposited film quality. This feature is popular with optical coaters for anti reflective (AR) coatings.

Laminar Flow Option

An optional laminar-flow attachment (above the process chamber) sends a curtain of filtered air across the chamber door. This protection from foreign matter permits system installation in less rigidly controlled environments.

Process Control Upgrade

SCT integrates GE Fanuc as the system software interface for PLC. In addition to the process controller, the built in control console houses source power supplies, thickness and rate monitors, tape reader, dual ion-gauge switch, dual thermocouple gauge and auto ranging, automatic vacuum control, heater power supply and the circuit breaker panel.

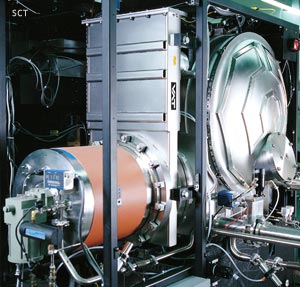

SCT 5000 – High Vacuum Evaporator

The SCT 5000 evaporator is a versatile system designed for high production, pilot production or research and development for optical, semiconductor and special applications.

It is a high performance system which is designed for fast servicing, and has a rear door for access outside the clean room.

An SCT exclusive is the short, straight through, conductance path which exposes less surface area to the vacuum. All high vacuum components are fabricated from electropolished type 304 stainless steel, sealed with a minimum number of Viton o-rings and gaskets. No pipe threads are used anywhere.

Air operated and electrically controlled automatic valve sequencing interlocked with the vacuum system controller ensures ease of operation and protection against normal operating hazards. This control includes automatic regeneration of the cryopump.

The SCT 5000 houses as many as three electron beam sources and can include other resistance sources. Substrate fixtures include a canted dome high speed planetary system. Also available is a 90˚ angle of incidence lift-off fixture. Horizontal planetary and rotating flat plate fixtures are also available. All fixtures come with variable speed drive motors.

The system can be equipped with the following power supplies: 3 or 6kW for dielectric type materials and 6, 10 or 15kW for highly conductive materials.

We offer as options substrate heat, various thin film deposition controllers and glow discharge or ion beam substrate cleaning.

Programmable High Vacuum System Controller with Data Logging Capabilities

SCT provides as a standard a GE Fanuc PLC industrial controller. This system includes ladder logic software with required programming for the SCT 5000. The operator/engineer computer interface includes a GE Fanuc Display Station 2000 (GE 15″ touch screen computer); GE “Cimplicity” HMI, or equivalent and all required software programming are also provided. The control system also performs data logging of all key process variables.

Deposition Sources

Multiple resistance sources or up to three 270˚ deflection single or multi-crucible electron beam guns may be installed for single, sequential or co-deposition purposes.

Substrate Fixturing

The SCT 5000 will accept high speed canted dome planetary systems, 90˚ angle of incidence lift-off domes, rotating horizontal plates, and static fixturing.

Custom Features

All of SCT’s systems are built to customer specifications, making each system unique. Our engineering department can make any desired modifications to the basic design so that we can provide you with a fully documented custom system tailored to your specific requirements.

As a company with a great deal of high vacuum expertise, we continue to develop new designs and improve the previous ones. We identify the best features in competing products and integrate them into ours.