SCT offers a low-cost version of the popular SE-600 and SE-1000 evaporation systems which were originally introduced by CHA Industries. The SCT Systems incorporate the best available components and controls to improve process performance and reliability.

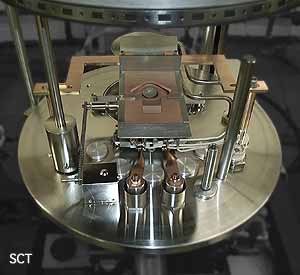

Evaporation Components

The SCT-600 and SCT-1000 normally incorporate Telemark e-beam components and deposition controller. An optical monitor is available as an option. Other e-beam equipment can be supplied when requested.

Large Roughing Line

The systems are equipped with 3 inch block manifold, roughing, and foreline valves. As in the high vacuum valve, the roughing and foreline valves are built around a vertical sealing plane to eliminate leaks caused by falling particles.

Superior Cold Trap

With over 250 square inches of cryogenic surface, the cold trap handles high volumes of condensable vapor. It has been specially designed to handle liquid nitrogen. Since typical holding time is from 10 to 14 hours, there is no need to interrupt a process cycle to refill the trap.

Efficient Operation

The system is designed for overall efficiency. This includes fast cycle time, maximum wafer capacity, ease of reloading, convenient servicing, and long system life. For example, to clean or inspect the O-ring on the high vacuum valve it is only necessary the pull the quick-release pin in the valve shaft and remove the sealing plate through the port in the base plate.

Vacuum System Equipment

All SCT series systems may be equipped with planetary fixturing in either a 19.5 or 25.5 inch stainless steel bell jar. Also available is an 18-by-30 inch Stainless steel bell jar which may be equipped with either planetary or static fixturing. All SCT series systems also include an all stainless steel valve/trap assembly that is internally welded to prevent virtual leaks.

Thoroughly rebuilt

CHA is a registered trademark of CHA Industries.